The working mode of Roots blower is that when the motor moves the driving shaft through the main shaft or pulley, the gear installed on the driving wheel rotates the gear installed on the driven wheel in the opposite direction at the same time, so that the engaged rotor rotates together. In this way, the casing and rotor form a space, and gas enters the space from the air inlet. At this time, the gas is compressed and pushed away from the discharge port by the rotor. The other rotor forms a new space with the other side of the shell relative to the first rotor and the position where compression begins. The new gas enters the space again, is squeezed, and continues to move to achieve the purpose of the fan.

The common cooling modes of Roots blower include water cooling and air cooling. The water cooling mode is to add a cooling water system and use cooling water for cooling; The air cooling mode is to increase the fan and exhaust duct to exhaust the heat of the fan indoors. Through operation, it is found that the water cooling mode will not have any impact on the indoor environment, and the air cooling mode will affect the environment of the machine room in summer.

Because the outdoor temperature in summer is higher than 40 ℃, the heat discharged into the room can not achieve the purpose of cooling, but also increase the indoor temperature. However, the air cooling mode will not affect the environment of the machine room in winter, so the cooling mode can be selected according to the time.

Auxiliary cooling measures. Generally, Roots blower can reduce temperature, water cooling and air cooling. Air cooling is used according to technical requirements, and water cooling is required for high temperature. In order to ensure the normal use of main auxiliary fuel tank, cooling treatment is required to reduce the temperature of lubricating oil. The temperature of general lubricating oil shall not exceed 65 ℃.

In winter, when the water-cooled roots blower is not used for a long time in winter, all refrigerated water should be drained to avoid freezing of refrigeration. For the design of impeller clearance, the clearance between impellers will also affect the cooling during the design of Roots blower. For example, the shell clearance, impeller clearance, wallboard clearance, etc. are also the key points of design. The design of some small enterprises is not perfect, and the service life of equipment is sometimes shortened.

The design of impeller clearance shall meet certain standards, and it shall also be checked during use. Dust and dirt on the impeller shall be treated to a certain extent during annual major inspection, so that the impeller clearance is within the standard error, and the spacing is not too small.

Strengthen protection of vulnerable parts. The lubricating oil is vulnerable to the high temperature of Roots blower, so the cooling treatment of lubricating oil needs to be protected in many ways. In addition to water cooling, it also needs to reduce the temperature from the inside of the shell to the wall panel and the lubricating oil in turn for cooling.

I believe that after reading the above contents, you should also understand the basic measures for cooling Roots blower. I hope it will be helpful to you.

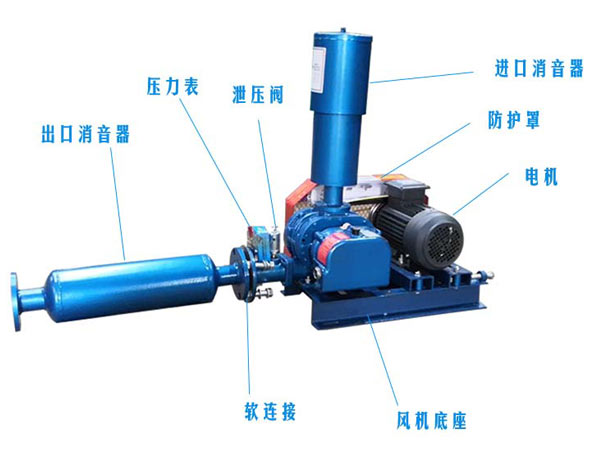

Text label: Roots blower

Article address: //wuhanzhcs.com/html/news/n02/87.html