Before starting Roots blower, check it first, including various parts, refrigeration control circuit, exhaust valve, oil reference line, motor steering and other related matters. As the saying goes, "If you kill a thousand people by mistake, you will not miss one". Before each operation of the equipment, check it to prevent problems that cannot be solved immediately will damage the equipment instead. If the equipment is restarted after a long time without application, it should be checked carefully, otherwise the motor may be damaged due to forced opening, causing great damage.

Secondly, the cooling circulating water valve of Roots blower must be opened before starting, the front stage pump must be started, and then the channel valve of the front stage pump must be opened. Until the front pump runs stably, open the bypass valve and close the exhaust valve, and then the equipment will start automatically.

Although the beginning of autumn has just passed, the temperature is still relatively hot. In the whole process of equipment operation, if the operating temperature is too high, the noise is abnormal or other abnormal conditions, the inspection should be stopped immediately. Before stopping the equipment, close the bypass valve and open the exhaust valve of Roots blower, and the equipment will stop automatically.

If it is not used for a long time, the Roots fan equipment can dry the water and then empty it, especially in winter and cold regions, to avoid freezing and damage to the waterproof casing.

Finally, pay attention to the maintenance if you want to make the Roots blower run efficiently. After the equipment is put into use, regular maintenance is very important. The lubrication condition of each component shall be checked frequently.

The maintenance and overhaul of Roots blower shall formulate a reasonable maintenance system according to the specific use situation, carry out it on schedule and make records. It is recommended to overhaul once a year, and replace the bearing and relevant vulnerable parts. Before disassembling the machine, measure and record the matching dimensions of Roots blower, and mark the parts to ensure that the original matching requirements are maintained after assembly.

Regularly check the fastening condition of each part of Roots blower and whether the locating pin is loose, and check that there is no oil leakage, scaling, rust and peeling in the body. Pay attention to whether the lubrication and heat dissipation are normal, pay attention to the quality of lubricating oil, often listen to the fan for noise, pay attention to whether the unit operates under the condition that does not meet the requirements, and pay attention to the regular grease.

Sometimes the overload of Roots blower is not displayed immediately, so pay attention to the increasing trend of inlet and exhaust pressure, bearing temperature and motor current to judge whether the machine operates normally. For new machines or overhauled three leaf roots blowers, the oil tank should be cleaned and put into operation according to the operating procedures. It is recommended to replace all lubricating oil after 8 hours of operation.

Routine maintenance of roots blower: pay attention to the bearing temperature, sound and vibration in daily work, and check the oil level of the oil pointer, oil temperature, inlet and exhaust pressure, ammeter index, etc. If conditions permit, replace the gear oil one day after the Roots blower starts normally, and you will find that the oil is dark yellow, black, and very viscous. This is because the oil on the bearing, the iron filings in the gearbox and the gear oil are mixed together, which is not conducive to gear lubrication. After this replacement, it will be replaced once every three months.

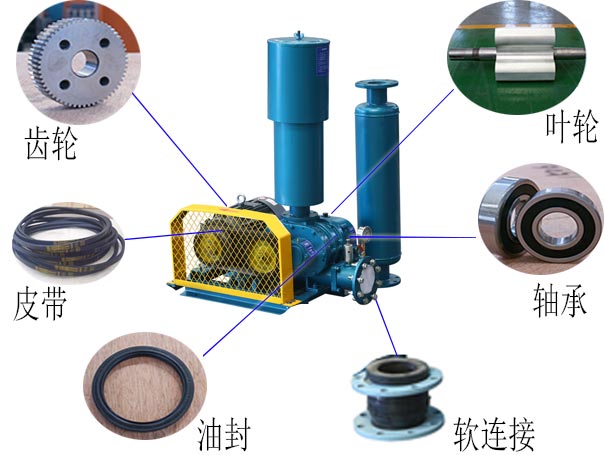

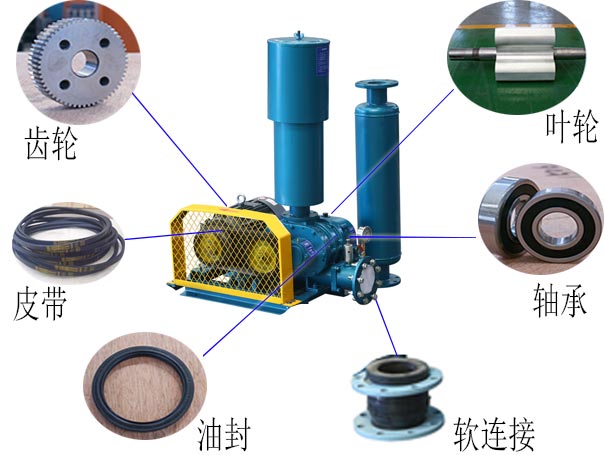

Monthly inspection: For fans with V-belt drive, the tension of V-belt should be checked regularly. Quarterly inspection: regularly clean the filter and replace the gear lubricating oil every quarter. Annual inspection: the gear, bearing, oil seal and gas seal of the fan shall be cleaned regularly every year. Check the condition inside the rotor and cylinder, and correct the clearance of each part.

I believe that after reading the above content, you should also understand the methods to improve the use skills of Roots blower. I hope it will help you.

Text label: Roots blower

Link to this article: //wuhanzhcs.com/html/news/n02/695.html