Roots blower is a kind of volumetric compression fan, whose core components are the rotor system including the main shaft, driven shaft, impeller and gear. It has been widely used in many fields such as petrochemical, electric power, smelting, food and sewage treatment due to its simple structure, no need of lubricating oil in the fan cavity, and smooth operation. Roots blower is one of the key equipment of the wet desulfurization process in power plants. When the limestone gypsum wet desulfurization method is adopted in the boiler system of thermal power plants, most of the Roots blower is used to blow sufficient air into the absorption tower to oxidize calcium sulfite in the slurry of the absorption tower, so as to generate calcium sulfate dihydrate that is easy for post-treatment. The stability of Roots blower operation directly affects the normal operation of the desulfurization system and the emission of environmental protection standards.

In winter, the room temperature is low, and the Roots blower operates well (when the room temperature is 5 ℃, the front bearing of Roots blower is about 80 ℃). In summer, when the room temperature reaches above 30 ℃, the front bearing of Roots blower exceeds the set tripping temperature as the room temperature rises. In order to avoid tripping, the crew added spray water on the casing to cool down as an emergency treatment measure, but the sanitary condition was poor during operation, which did not fundamentally solve the problem.

When Roots blower is shut down for inspection after a period of operation, it is an essential work for equipment management personnel to inspect the inside of the blower. However, the inspection of the inlet and outlet pipeline system of the blower is mostly in a state of neglect of management, which is easy to lead to scaling inside the pipeline without timely cleaning. The scale formation can be reduced to a certain extent by improving the quality of the outlet air temperature desuperheating water and the atomization effect; Check the outlet pipeline regularly to ensure that the outlet pipeline is unblocked, so as to ensure the normal operation of the fan.

Measures for prolonging the service life of Roots blower motor bearing:

When Roots blower is running, ensure that the oil level is between the two red lines of the oil level gauge. Too little oil will lead to poor lubrication of gears and bearings; Too much oil will cause the oil temperature to rise and damage the gear and other parts. The lubricating oil shall be of reliable and guaranteed quality. When filling the lubricating oil, the lubricating oil shall be added to the oil level gauge. After the blower and vacuum pump run, the oil level will drop slightly.

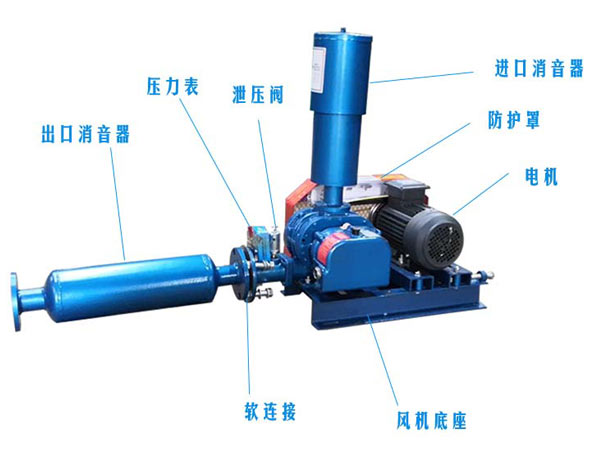

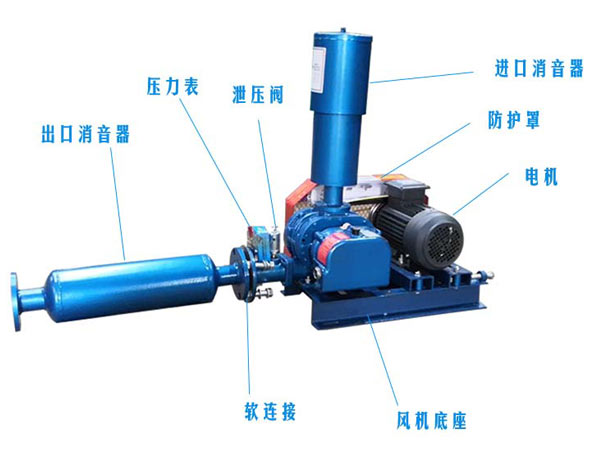

When the Roots blower and vacuum pump are driven by the intermediate shaft pulley, the bearing blocks at both ends of the intermediate shaft shall be filled with No. 2 general lithium base grease, and the filling amount shall be 1/2~1/3 of the free space of the bearing block. Roots blower is mainly composed of casing, wallboard and two rotors with impellers. Through the action of a pair of synchronous gears, the two rotors rotate at the same speed in the opposite direction, and the suction chamber and exhaust chamber are basically isolated by the clearance between the impeller and the impeller, and the impeller and the casing. With the help of the impeller rotation, the gas in the casing volume is driven to achieve the purpose of air blowing.

Roots blower adopts frequency conversion control, which can accurately control the air volume. Compared with valve control, it is more intuitive and convenient to adjust the air volume of the blower to meet production needs; Due to the frequency conversion technology, the motor can realize soft start without starting current impact; The motor was started directly when the frequency converter was not used, and the starting current was up to 200 - 300A, which had adverse effects on the motor or the power grid. As the rotating speed of Roots blower is reduced to 60% of the original, the vibration frequency and noise of blower pipe are greatly reduced, the mechanical life of blower and motor bearing is extended, and the amount of equipment maintenance is reduced.

Methods to reduce the bearing temperature of Roots blower:

The bearing temperature of Roots blower will also be affected by the external environment. In winter, the room temperature is low, and the Roots blower operates well (when the room temperature is 5 ℃, the front bearing of Roots blower is about 80 ℃). In summer, when the room temperature reaches above 30 ℃, the front bearing of Roots blower exceeds the set tripping temperature with the rise of room temperature. In order to avoid tripping, the crew added spray water on the casing to cool down as an emergency treatment method, but the sanitary condition was poor during operation. The following are simple and quick methods to reduce the bearing temperature of Roots blower.

1. The simple and practical way is to install sunshade outside the fan, which is one of the direct methods of cooling.

2. If the temperature of axial flow fan, wear-resistant fan and other fans rises too high, it is likely that the air inlet and outlet pipe gates are not closed when the fan is running. Solution: just close the gate of the gas inlet and outlet pipes.

3. In addition, due to the violent vibration of the box, the installation of shaft and rolling bearing is skewed, the front and rear bearings are not concentric, and the fan rolling bearing is damaged or the shaft is bent, which is one of the factors affecting the temperature of the fan bearing. The solution: timely change the lubricating oil to reduce the friction coefficient.

4. The motor belt is too loose. In this case, the motor belt should be replaced in time, and the position of the belt pulley should be adjusted to make it evenly stressed.

I believe that after reading the above, you should also understand the methods and techniques to reduce the bearing temperature of Roots blower. I hope it will be helpful to you.

Text label: Roots blower

Link to this article: //wuhanzhcs.com/html/news/n02/689.html