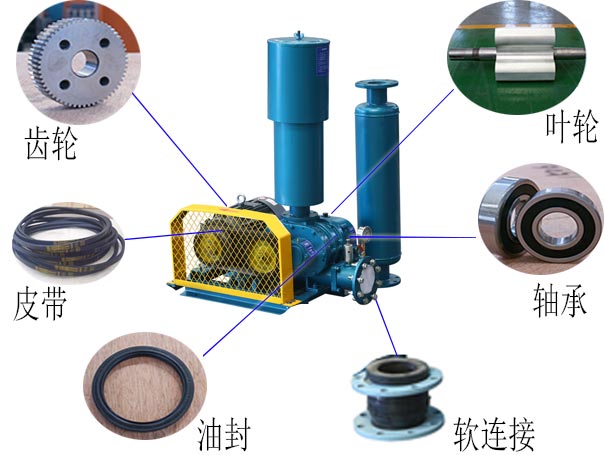

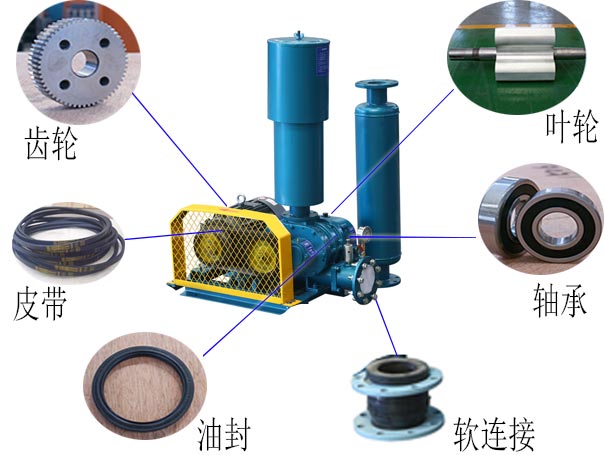

Trefoil Roots blower What is the adjustment of the belt device? (1) Belt pulley alignment. Starting from the end point A of the wheel, along the direction of the center lines of the two wheels, close a ruler (or pull a string) to the end face of the wheel. If the ruler can contact four points A, B, C, D on the end faces of the two pulleys at the same time, it means that the end faces of the two wheels are flush and the installation position is correct. Otherwise, if the pulley is not in the correct position, it will not only shorten the service life of the belt, but also will not affect the operation of the machine, so it must be adjusted. The adjustment method is as follows: ① If the blower is parallel to the motor axis, but the end faces of the two wheels are uneven, the wheel protruding from the curtain can be driven in appropriately. ② If the two shafts are not parallel, loosen the connecting bolt between the motor and the base, and adjust the motor axis. ③ If the leather belt is not properly tightened, the motor axis should be horizontally translated.

(2) The belt tightness of three blade roots blower should be appropriate, and the common inspection methods are:

1. Measure the distance t (mm) between the belt and the contact points of two pulleys.

2. Use a spring scale to measure the external force W acting vertically on the midpoint of the belt. When the deflection S meets the S-0.0161 (tight fit lom) relationship, if the external force must meet the requirements of 9-2, the belt is loose

3. If the measured external force is too small or too large, it means that the belt is too loose or too tight, so it should be adjusted. If the tension is too tight, the life of the belt and bearing will be shortened. If the tension is too loose, the belt will slip and vibrate, resulting in early damage of the belt.

(3) Installation and adjustment of three blade roots blower belt. Attention should be paid to the following issues: 1. When installing the belt, the center distance between the two wheels should be reduced first, and then the belt should be installed. Do not pry people forcibly.

2. Do not wax the belt or pulley.

3. Even belts of the same model and specification have different manufacturing errors in length. Therefore, it is better to select belts of the same length or similar length into groups and use them together.

4. When replacing belts, all belts should be replaced at the same time. It is not allowed to mix new and old belts. Otherwise, the length of the belt varies, and the load will be concentrated on the new belt.

5. The new belt may have fatigue relaxation after running for a few minutes after installation, so it should be tensioned in time.