Roots blower is a volume rotary blower. The compressor keeps the two rotors engaged by the synchronous gear at the rotor shaft end. Each concave curved surface on the rotor forms a working volume with the inner wall of the cylinder. During the rotation of the rotor, the gas is taken away from the suction port. When the rotor moves to the exhaust port near which it is connected with the exhaust port, the pressure in the working volume suddenly rises due to the backflow of high pressure gas, and then the gas is transported to the exhaust channel. The two rotors do not contact each other, and they are sealed by a tightly controlled gap, so the discharged gas is not polluted by lubricating oil.

First of all, confirm whether the industry needs to use the "blowing" or "suction" function of the blower. The blowing function is called pressure fed roots blower, referred to as roots blower; The suction function is called vacuum roots blower, referred to as roots vacuum pump and vacuum pump.

Secondly, it is necessary to know the parameters of air volume, air pressure, wind speed and so on. If the specific requirements for these parameters are not clear, it is necessary to consult our professional technicians or representatives who sell blowers, and select the appropriate blower head according to the opinions of professionals.

Then it is about the selection of motor. The motor and model selection matched with the blower are also particularly important. Too much power of the motor will lead to waste of power; If the power is too small, the motor will burn. Therefore, the selection of motor power should also be communicated with professional technicians or sales representatives.

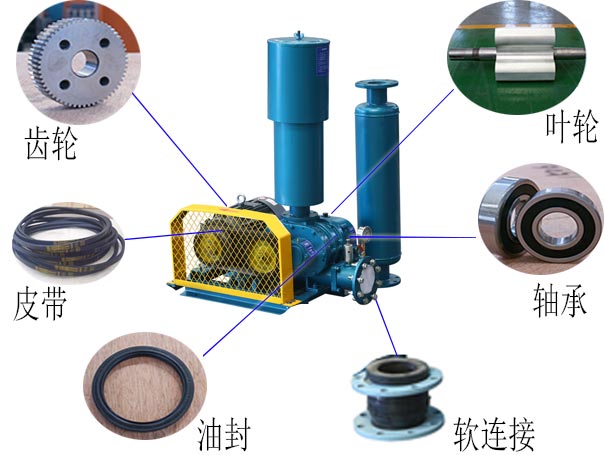

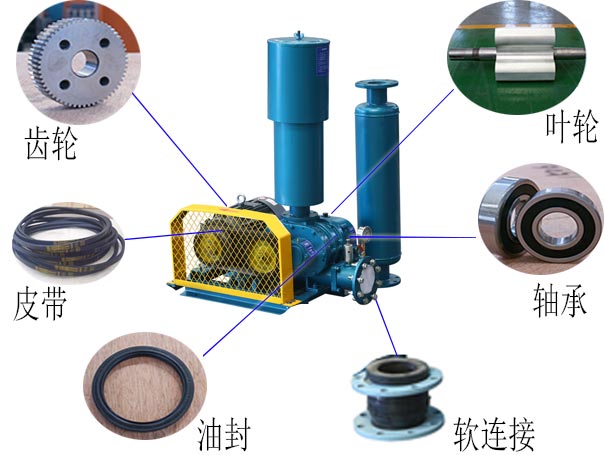

The last is the selection of accessories. The accessories of Roots blower include: common base, motor seat, belt, host pulley, motor pulley, belt shield, safety valve, pressure gauge, outlet silencer, inlet silencer, three-way, flexible joint, check valve, screw, asbestos gasket, etc. Select appropriate accessories according to specific installation requirements.

The pipeline is blocked because the air outlet of the fan is not smooth, and the air cannot be discharged. The pressure rises, causing the motor to form overpressure and wear, and then causing the equipment ammeter to rise. Misoperation current overload may also be a problem during operation. For example, when the check valve of the device is reversed and the gate valve is not fully opened, such operation may cause instantaneous burning of the motor.

Due to the adoption of a three blade rotor structure and a reasonable structure at the inlet and outlet of the housing, the fan has low vibration and noise. The impeller and shaft are of integral structure, and the impeller is free of wear. The performance of the fan is permanent and can operate continuously for a long time. The fan has large volume utilization rate, high volume efficiency, compact structure and flexible installation mode. The selection of bearings is more reasonable, and the service life of each bearing is even, thus extending the life of the fan!

The operation shall be carried out according to the regulations, and unnecessary trouble caused by carelessness shall be avoided. Lubricating oil If the equipment is short of lubricating oil, and the fan continues to operate under the condition of oil shortage, the impeller problems will conflict and the gears will wear each other more, and then increase the motor load, which will only add the motor burden and accelerate the loss.

The blower itself has its own quality problem when it leaves the factory. When installing the blower, many parts have poor clearance cooperation, which will form a rated conflict. In addition, some parts may be damaged, increase the motor load, and cause the fuse to blow. Air outlet problem If the air blower fails to go out, the pressure will rise and the motor load will be increased in the same way, which will lead to excessive current.

1. Whether there is no lubricating oil at all parts of the blower; Roots blower needs regular maintenance. When it works in the state of oil shortage, the friction will increase and the motor load will increase, resulting in excessive current.

2. Whether the air outlet of the blower is smooth; If the wind beat cannot go out, the pressure will rise, which will also increase the motor load, resulting in excessive current.

3. Blower quality problems; Poor clearance of many parts will cause additional friction. In addition, some parts may be damaged, increasing the load of the motor, and causing the fuse to blow.

Text term label: Roots blower

Link to this article: //wuhanzhcs.com/html/news/n02/664.html