What are the applications of Roots blower for sewage treatment?

Source: Roots blower manufacturer

Published on: November 1, 2023

Hits:

Related information

-

What is the function of Roots blower for sewage treatment? -

What is the function of Roots blower for sewage treatment? -

What are the main functions of Roots blower for sewage treatment? -

How to calculate the air volume of Roots blower in the aeration tank of WWTP? -

Operation requirements and maintenance rules of Roots blower for sewage treatment: -

Introduction to pressure, air volume and type selection of Roots blower for sewage treatment: -

Proper use of Roots blower for sewage treatment: -

Roots blower for sewage treatment plays a big role in the environmental protection industry and is highly efficient! -

What is the function of Roots blower for sewage treatment? -

Roots blower is also a necessary core electromechanical equipment in the sewage treatment aeration tank, helping the development of environmental protection industry

Xinqianshun's latest products

Random articles

-

What is the cause of belt heating when Roots blower is running? -

What are the skills for selecting Roots blower in the field of environmental protection? -

Why does the motor of Roots blower burn out due to excessive current -

How to deal with water inflow during the use of Roots blower? -

Precautions and steps before starting Roots blower, I know what you think! -

High pressure roots blower uses some simple methods to reduce noise: -

Introduction to common faults and maintenance of Roots blower -

Causes of Roots blower tripping and simple solutions -

Is the price of two-stage series roots blower high? -

How to do a good job in the trial operation of Roots blower after installation?

Latest news articles

-

Application of Roots blower for special gas transportation -

Function and characteristics of Roots blower for special gas transportation -

Precautions for piping and pipe installation of high-pressure roots blower -

Introduction to matters needing attention in model selection of three blade roots blower -

The manufacturer of explosion-proof roots blower explained the reasons for its high temperature? -

Difference between direct connected roots blower and belt connected roots blower and precautions for model selection -

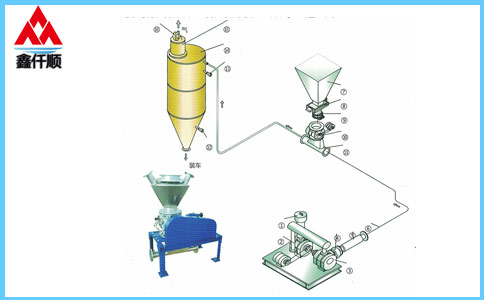

Roots blower for material pneumatic conveying plays an important role in pneumatic conveying: -

The selection of roots blower for pneumatic conveying is carried out from the following aspects: -

What are the selection principles and main uses of Roots blower for powder conveying? -

Calculation Method for Selection of Roots Blower for Material Conveying