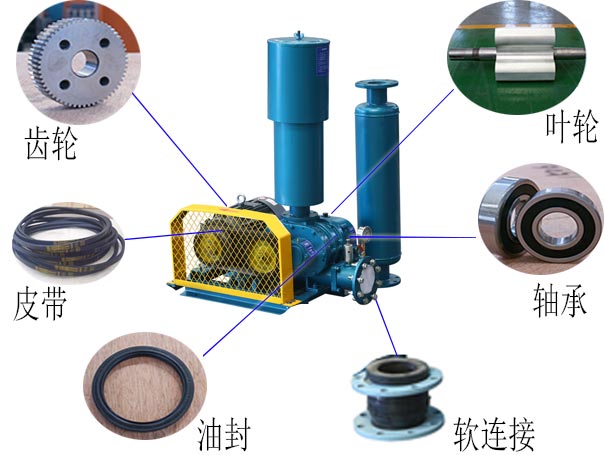

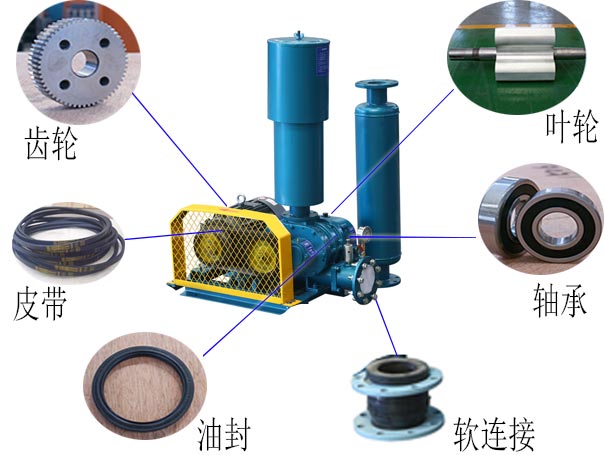

Roots blower has low vibration and noise due to the use of three blade rotor structure and reasonable structure at the inlet and outlet of the housing. The impeller and shaft are of integral structure, and the impeller is free of wear. The performance of the fan is permanent and can operate continuously for a long time.

The fan has large volume utilization rate, high volume efficiency, compact structure and flexible installation mode. The selection of bearings is more reasonable, and the service life of each bearing is even, thus extending the life of the fan. The fan oil seal is made of imported fluororubber material, which is high temperature resistant, wear-resistant and has a long service life.

There are two main reasons for bearing end face wear. One is that foreign matters enter the end face of rotor and bearing seat, which is too rare to be analyzed here. The other is that the axial clearance is not enough, which causes the contact wear between the rotor and the bearing end face when the rotor expands online. We know that the molecules of any substance are doing irregular thermal movement, so the molecules have speed and kinetic energy.

Microscopically, the pressure of gas is the impact of a large number of molecules on the container wall, and the temperature is the measurement of the average kinetic energy of the thermal movement of a large number of molecules. The higher the temperature is, the greater the average kinetic energy of the molecular thermal movement is, and the greater the molecular speed is. We know that the greater the speed is, the more violent the impact is, that is, the greater the pressure of the gas is. When the fan generates pressure, on the contrary, the gas will generate temperature. The temperature causes the rotor to stretch, and if the clearance is not enough, it will cause friction between the rotor and the casing.

Too large axial clearance will reduce fan efficiency. As the three leaf roots blower is a positive displacement fan, its wind pressure has something to do with the system, but has little to do with others. That is to say, it has a certain relationship with the characteristics of the outlet pipe. The flow rate has a great relationship with the fan speed. However, if the axial clearance is adjusted too large, a gas channel will be formed at the impeller end face and the bearing seat end face. The gas channel will make the air being boosted return to the suction port of the fan through it, making the fan continuously do quantitative reactive work, reducing the fan air volume and efficiency.

The axial clearance adjustment of Roots blower is mainly based on the calculation data, and the end positioning bearing is used to adjust the entire clearance.

1. Measure the distance X between the two end faces of the casing;

2. Measure the distance Y between two end faces of the rotor;

3. X-Y=&, where&is the total gap size,&1+&2=&. If the&value is less than the C value, add a cushion between the bearing pedestal and the end face of the casing for adjustment; If the&value is greater than the C value, the casing end face needs to be machined to remove materials. The standard adopted is&value is 0.20mm higher than C value. This 0.20mm is the empirical value used to compensate the installation error;

4. The inner ring of the bearing is in contact with the shaft shoulder, and there is a clearance S between the outer ring of the bearing and the locating ring of the outer ring of the bearing seat. When the outer end cover is fastened with bolts, the bearing pushes the whole rotor forward, and the value of&2 gradually increases. Therefore, add shims at the clearance S to make the&1,&2 values reach the required clearance.

5. In actual work, two methods can be used to determine the gasket thickness. One is the measurement method, which mainly uses the depth vernier caliper to measure the S value, and then S&2=K. K is the shim thickness. The other method is the additional test method. The additional test method uses a false shaft sleeve. The outer diameter of the shaft sleeve is 1mm smaller than the outer ring of the positioning bearing, and the inner diameter is 1mm larger than the shaft. The thickness is the standard bearing thickness. Try to add shims at the place where shims are added each time, and then tighten the shaft sleeve according to the standard. Use a feeler gauge to measure the&2 value, and the straight&2 value reaches the standard value.

6. The relationship between&1 and&2 is 2:1. That is, when&1 is 0.30mm,&2 is 0.15mm. The purpose of this is to increase the expansion clearance at the free end of the rotor.

I believe that after reading the above, you should also understand the adjustment skills of the axial clearance of Roots blower. I hope it will be helpful to you.

Text label: Roots blower

Link to this article: //wuhanzhcs.com/html/news/n02/650.html