Roots blower manufacturer Example of Roots blower for aquaculture [Purchase Tel.: 0531-83663588]

Metallurgy is divided into ferrous metallurgy and nonferrous metallurgy, of which steel production is the main part. In the past, the Ministry of Metallurgy, today's metallurgical industry associations, mainly iron and steel joint enterprises, use of Roots blowers in the metallurgical industry is basically the use of Roots blowers in iron and steel plants;

The impeller adopts involute linear, advanced and reasonable, with high efficiency, excellent material, long service life and low noise. Forced lubrication, high pressure rise, high rotor balance accuracy, low vibration, safe and reliable long-term operation. The main parts are processed by numerical control equipment, and the gears are of 5-grade precision, which makes the products have high precision and reliable operation. The casing and wallboard adopt a central split structure, which is convenient for maintenance. Compact structure, small size, light weight, easy to use and maintain.

In October 2020, the project leader of Jiangsu Metallurgical Equipment Co., Ltd. visited our company, and the procurement is applicable to Roots blower for steel plant industry 。 Xinqianshun technicians introduced the important position of fans in smelting industry to purchasers. The main smelting processes from ore to steel making include ore sintering, ironmaking and steelmaking, that is, fans are required in all processes of steel smelting. After the introduction, the customer was full of praise for the professionalism of our technical personnel, and finally purchased eight three blade roots blowers, two of which were used as standby. Roots blower for steel plant industry Use of:

The ore for smelting shall be sintered before smelting. Sintering machine shall be used for sintering, and the main exhaust fan and cooling fan of flue gas shall be used for sintering furnace.

2. Roots blower for coke oven gas transmission

Coke is the main fuel and reducing agent for steel smelting, as well as the proppant and loosening agent for the particles in the blast furnace. After being pumped out by the fan, the gas in the coke oven must be partly used as the fuel of the coke oven, partly pressurized and sent to the steel plant as the fuel, and the other part used to produce other by-products.

The typical representative product of coke oven gas transportation is Roots blower. Its main structural feature is that the unit is composed of motor, gear booster engine, centrifugal blower, lubrication system and instrument control system. The casing is of horizontal split structure, and there are horizontal and longitudinal positioning keyways under the bearing box to keep the body well aligned and adapt to the thermal expansion of the casing; The bearing box and housing are cast together to enhance rigidity and facilitate disassembly and maintenance.

The rotor is composed of main shaft, impeller, spacer sleeve, balance plate and half coupling; The impeller is welded with high-strength alloy steel.

The bearing is divided into support bearing and thrust bearing. The support bearing is elliptical pad sliding bearing, and the thrust bearing is Mitchell double-sided thrust sliding bearing.

The seals are located between stages, at the inlet of impeller, around the balance plate and at both ends of the shaft. They are labyrinth type snap ring seals.

3. Blast furnace blower

In the process of pig iron smelting, the blast furnace blower must be used to transport a certain amount of combustion supporting air (or oxygen) to the blast furnace to increase the furnace temperature. In addition, it is necessary to send combustion air to the centrifugal fan in the hot blast furnace.

The oxygen for the iron and steel industry lies in strengthening the smelting process. In steelmaking, it is used for oxygen top blown converter steelmaking, oxygen bottom blown converter steelmaking, open hearth furnace oxygen blowing steelmaking, electric furnace oxygen steelmaking, etc. In particular, oxygen top blown converter steelmaking has become a major way for the rapid development of iron and steel industry. The amount of oxygen used in steelmaking is very large. It is obtained by deep freezing from the air using air separation equipment. Air compressor, oxygen compressor, heating blower and turbine expander must be used in each set of oxygen generator, which is commonly referred to as the "four major oxygen generators".

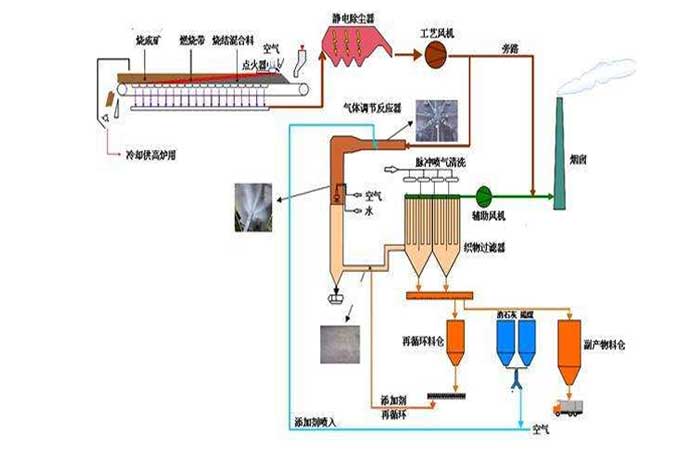

4. Converter secondary flue gas dedusting fan

The converter secondary flue gas dedusting system refers to the flue gas collection and dedusting at all dust raising points except for the purification and recovery of converter flue gas. Including converter iron mixing, converter converting, argon blowing station, hot metal slagging station and hot metal pouring station.

5. Centrifugal compressor for power station of steel plant

Centrifugal compressor is developed on the basis of imported technology. The main feature is the overall assembled structure, and a common base is used for the compressor, gearbox, intermediate gas cooler and lubricating oil system. The inlet is equipped with inlet regulating blades, which is the most economical method to optimize the operating performance of the compressor at non operating points. The inlet regulating blade is automatically adjusted according to the actual operation on site, which can realize the constant pressure output of the compressor outlet in the change of air flow.

6. Cupola fan

In addition to the fans required in the steel smelting process, the cupola (such as cupola, oil furnace and pulverized coal furnace) commonly used in general mechanical foundry plants need to use blowers (high-pressure fans or blowers) to press enough air to support combustion.

7. Blast furnace gas residual pressure recovery turbine power generation device

The blast furnace gas residual pressure recovery turbine power generation device is an energy recovery device that uses the gas pressure at the top of the blast furnace to expand and work through the turbine to drive the generator to generate electricity. The TRT device not only recovers the energy released by the original pressure relief valve (about 30% of the energy required by the blast furnace blower), but also purifies the gas, and improves the control quality of the blast furnace top pressure.

Development trend of Roots blower in metallurgical industry in the future

Although there are many types of fans used in metallurgical industry, they are relatively difficult. There are three types that can represent the design and manufacturing level of fans, namely axial flow compressor, sintering induced draft fan and gas conveying roots blower. For these three types of fans, the technical level of foreign countries is higher than that of domestic countries, and the advanced technical level of foreign countries is the future development trend that should be actively pursued at home.

1. Axial compressor

Axial compressor is characterized by high efficiency, large capacity, wide performance adjustment range, etc. At present, axial compressors are used for blast furnaces above 1000m3 abroad. As an axial compressor for blast furnace blowing, its flow has reached 10000m3/min, pressure has reached 0.69MPa, and power has reached 70000kW.

In recent years, in order to improve the efficiency of axial compressor, sound insulation and noise elimination have been put on abroad. The measures are: (1) using thickened casting casing to reduce noise scattering; (2) Sound insulation cover and muffler are used to reduce noise diffusion. The computer is used as the central command system of regulation to realize the regulation automation and operation optimization of axial compressor.

2. Sintering induced draft fan

As the main smoke extractor of sintering machine, sintering induced draft fan accounts for more than 50% of the total power consumption of sintering plant. Because the medium conveyed is sintering flue gas, which contains a large amount of dust, improving efficiency, reducing energy consumption, strengthening wear resistance measures, and improving service life are still the main technical topics of sintering induced draft fan.

The air volume of sintering induced draft fan depends on the sintering area of sintering machine; The pressure depends on the thickness of the sinter layer.

The large-scale sintering machine (which can produce 1000m2 sintering machine) and thick material layer (which has reached 700mm) have promoted the development of sintering induced draft fan towards large air volume and high negative pressure. The maximum flow of sintering induced draft fan is 40000 m3/min, the maximum pressure is 19620Pa, and the maximum power is 14500kW.

Due to the constraints of manufacturing process conditions and transportation conditions, the sintering induced draft fan matched with the oversize sintering machine often adopts the parallel connection of two machines.

Wear resistance measures for sintering Roots blower:

(1) The zigzag middle plate can not only improve the flow distribution at the outlet of the impeller and reduce GD2, but also avoid the erosion of flue gas against the middle plate;

(2) The blade is equipped with replaceable wear-resistant liner (tungsten carbide surfacing on the liner surface);

(3) The replaceable cone disc protects the middle disc from wear;

(4) The casing is equipped with scroll lining plate and side lining plate;

(5) The surface is coated with ceramic anti-wear coating, resin coating, quartz powder and water glass coating;

(6) Surface strengthening surface surfacing, thermal spraying, boronizing, laser surface hardening and high-frequency quenching.

At present, the research on two-phase flow (solid particles and sintering flue gas) in the aerodynamic design and calculation of sintering induced draft fan is being carried out abroad, in an attempt to further solve the wear problem of sintering induced draft fan from the aspect of aerodynamics.

The device has developed rapidly and has a high level.

With the development of metallurgical industry, the selection of Roots blower is particularly critical as gas transmission is an important link in the process of metallurgical industry. Appropriate roots blower can reduce noise, improve work efficiency and improve production quality. With the development of science and technology, the future Roots blower will be automated, integrated and efficient.