Trefoil Roots blower It is a positive displacement blower, which separates the air inlet through the engagement of a pair of rotors (there is a gap between the rotors and they do not contact each other). The rotor is driven by a pair of synchronous gears and moves in the opposite direction, pushing the inhaled gas from the suction inlet to the exhaust outlet without internal compression. When the gas reaches the exhaust port, it is pressurized due to the backflow of high-pressure gas at the exhaust side, thus completing the gas transmission.

Working principle of Roots blower: use two mutually engaged and counter rotating three blade rotors to forcibly move the gas at the air inlet to the exhaust port to form a continuous and stable airflow. The exhaust port side of the casing is provided with a return groove to eliminate pressure fluctuation and reduce exhaust noise.

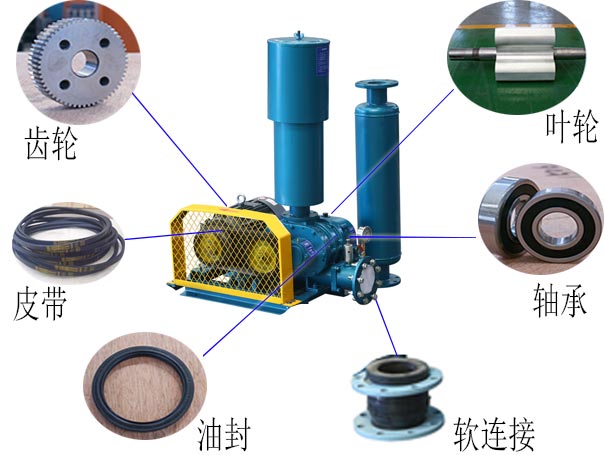

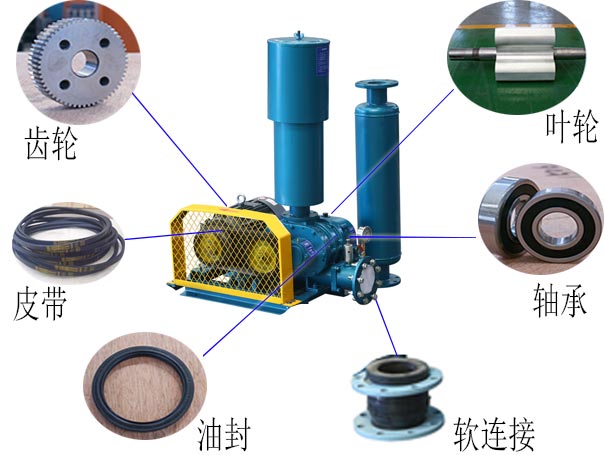

Roots blower accessories: blower host, belt, motor pulley, belt cover, base, inlet silencer, outlet stub pipe, safety valve, pressure gauge, pressure gauge switch, outlet silencer, shockproof joint, check valve, motor.

1. Casing

The casing is a cylinder body with oval section, which is generally made of high-strength cast iron. Stainless steel can be used to transport corrosive gases. The cylinder body is equipped with inlet and exhaust ports, and the outside is cast with stiffeners and mounting feet, which are mostly integral structures. Some large-sized casings also adopt horizontal split structure, and the upper and lower casings are positioned with pins

2. Wall panel A wall plate is arranged between the casing and the main and auxiliary oil tanks. Its function is to act as an end cover to seal both ends of the casing; The second is to support both ends of the rotor as a support. The one near the shaft extension end is called the front wall panel, and the one at the other end is called the rear wall panel. Some wallboards are equipped with side plates, which are embedded into the casing port during assembly to meet the requirements of rotor radial positioning; Even if wear occurs during operation, only the side panel needs to be replaced, so as not to scrap the whole wall panel. The wallboard is generally made of high-strength cast iron. When conveying corrosive gas, it is usually made of stainless steel as the casing.

3. Rotor

The rotor is usually formed by the combination of impeller and shaft through hot sleeve or cold pressing, and can be active or driven. The shaft is made of high-quality carbon steel or high-strength alloy steel, and the driven shaft is relatively short. The impeller is generally made of high-strength cast iron, and if necessary, it is made of stainless steel. The small rotor can also form the impeller and shaft as a whole, which are cast with high-strength ductile iron. In order to reduce the weight, the impeller head is often made into a hollow structure.

The rotor is divided into two leaves and three leaves according to the number of impeller heads, and straight leaves and twisted leaves according to the shape of the impeller. The two blade rotors are straight blades, and the three blade rotors have two shapes of straight blades and twisted blades.

4. Synchronous gear

The function of synchronous gear is to transmit power, and to determine the clearance between two impellers to ensure the synchronous operation of two rotors. The driving and driven gears have the same meshing parameters, and are a pair of cylindrical gears with a transmission ratio equal to 1:1. In order to facilitate circumferential adjustment, driven gear is mostly composed of ring gear and hub. When adjusting, rotate according to the specified rotation direction. When rotating in the opposite direction, the gear side clearance will be empty to the other side of the gear slot, and the clearance between the driving and driven impellers will change accordingly. The gear has several tooth types, such as straight teeth, helical teeth and herringbone teeth, and is generally made of high-quality carbon steel or high-strength alloy steel. The gear and shaft, ring gear and hub are cylindrical fit or taper fit. When cylindrical fitting is adopted, flat keys for fixing are installed between the mating surfaces.

5. Bearing

As far as bearing capacity is concerned, it is mainly radial load. When the synchronous gear is straight tooth or herringbone tooth, there is no axial force; When helical gears are used, a certain axial force will be generated, but the load is small. Common bearings include deep groove ball bearings, self-aligning roller bearings, angular contact ball bearings and cylindrical roller bearings. Cylindrical roller bearings are mostly used as load bearing, and other bearings can not only load but also play an axial positioning role on the rotor.

6. Seal

The purpose of sealing is mainly to prevent leakage of gas and lubricating oil. The quality of sealing can reflect the level of product design and manufacturing and the quality of service performance to a certain extent. Especially when conveying flammable, explosive or toxic gases, sealing is a key factor related to the safe operation of Roots blower.

There are two main types of seals. One is the sealing of fixed parts, such as the sealing between wallboard and casing, between wallboard and oil tank, and between bearing gland and bearing seat, which is called static sealing; The other is the seal of the moving parts, such as the seal of the shaft end, the tail of the bearing seat and the shaft extension, which is called dynamic seal (or shaft seal). The static seal structure is simple, generally rubber asbestos plate, O-ring, etc. The shaft seal structure is relatively complex, and the commonly used types are labyrinth seal, skeleton oil seal group, expansion ring seal, packing seal and mechanical seal.

The above are the components of Roots blower. I believe you will understand it after reading it. I hope it will be helpful to you.