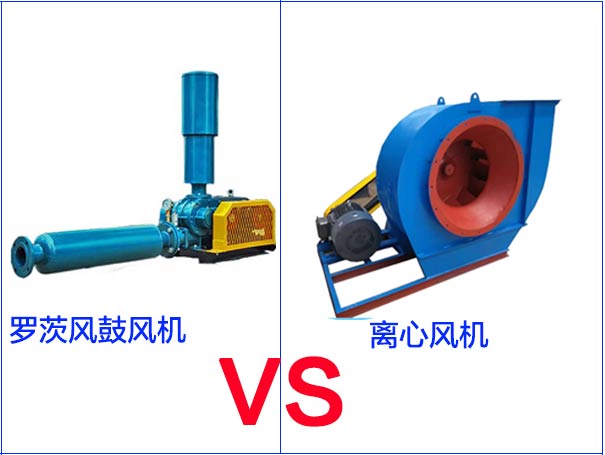

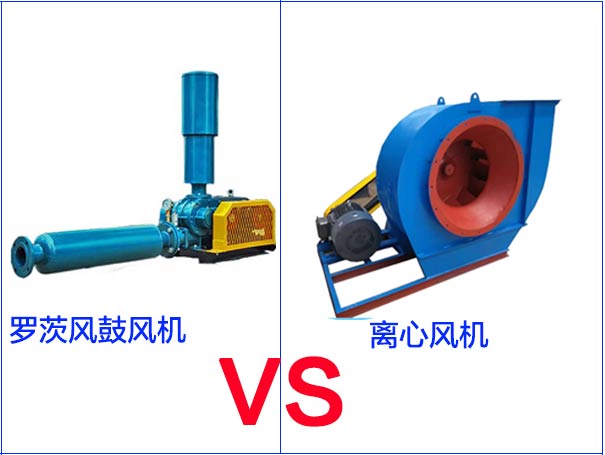

What are the differences between Roots blower and centrifugal blower?

Working principle of centrifugal blower When the motor rotates to drive the fan impeller to rotate, the gas between the blades in the impeller also rotates, and under the action of centrifugal force, these gases are thrown out, the gas flow rate increases, so that the gas can convert kinetic energy into static pressure energy in the flow, and then with the increase of fluid pressure, the static pressure energy is converted into speed energy, and the gas is discharged through the exhaust port, A certain negative pressure is formed in the middle of the impeller. Because the inlet is negative pressure, the external gas is immediately replenished under the action of atmospheric pressure, and the gas is continuously discharged and replenished under the action of continuous rotation of the impeller, so as to achieve the purpose of continuous blowing. Under the same power, the air pressure is inversely proportional to the air volume. Under the same power, if the air pressure is high, the air volume will be relatively low, and if the air volume is large, the air pressure will be lower, so as to make full use of the efficiency of the motor.

Working principle of Roots blower and Roots blower Working principle: Roots blower is a volumetric fan, and the air volume delivered is proportional to the number of revolutions. Each time the three blade impeller rotates, two impellers suction and exhaust for three times. Compared with the two blade impeller, the gas pulse is less, the load changes less, the mechanical strength is high, the noise is low, and the vibration is small. Two three blade impellers are set on the two parallel shafts. There is always a small gap between the wheel and the inner hole surface of the elliptical case and between the three impellers. Because the impellers rotate at a constant speed in opposite directions, a certain amount of gas surrounded by the case and the impeller is transported from the suction side to the discharge side. Each impeller is always kept in the correct phase by the synchronous gear, which will not touch each other, so it can be high-speed, does not need internal lubrication, and has simple structure, stable operation, stable performance, suitable for a variety of purposes, and has been used in a wide range of fields.

Characteristics of Roots blower

Due to the adoption of the three blade rotor structure and the reasonable structure at the inlet and outlet of the housing, the fan has low vibration and noise.

The impeller and shaft are of integral structure, and the impeller is free of wear. The performance of the fan is permanent and can operate continuously for a long time.

The fan has large volume utilization rate, high volume efficiency, compact structure and flexible installation mode.

The selection of bearings is more reasonable, and the service life of each bearing is even, thus extending the life of the fan!

The fan oil seal is made of imported fluororubber material, which is high temperature resistant, wear-resistant and has a long service life.

Complete models can meet the needs of different users for different purposes.

Roots blowers are widely used in petrochemical, building materials, electricity, smelting, fertilizer, mines, ports, light textile, food, paper making, aquaculture and sewage treatment, environmental protection industry and many other fields, mostly used to transport air, but also used to transport gas, hydrogen, acetylene, carbon dioxide and other flammable, explosive and corrosive gases.

At present, the consumption of Roots blower in sewage treatment industry and pneumatic conveying industry is the largest centrifugal fan

Function of centrifugal fan

Centrifugal fan is a kind of driven fluid machine, which relies on the input mechanical energy to increase the gas pressure and discharge gas.

Centrifugal fans are widely used for ventilation, dust removal and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings; Ventilation and induced draft of boiler and industrial furnace; Cooling and ventilation in air conditioning equipment and household appliances; Drying and selection of grain; Wind source of wind tunnel and inflation and propulsion of hovercraft.

The working principle of the centrifugal fan is basically the same as that of the turbine compressor, but because the gas flow rate is low and the pressure changes little, it is generally unnecessary to consider the change of the gas specific volume, that is, treat the gas as an incompressible fluid.

History of centrifugal fan

Fans have a long history. China has made simple wooden rice hulling windmills for many years before BC. Its working principle is basically the same as that of modern centrifugal fans. In 1862, the British Guibel invented the centrifugal fan. Its impeller and casing are concentric circles. The casing is made of bricks. The wooden impeller uses straight backward blades. Its efficiency is only about 40%. It is mainly used for mine ventilation. In 1880, people designed a volute casing for mine ventilation and a centrifugal fan with backward curved blades. The structure has been relatively perfect.

In 1892, France developed the cross flow fan; In 1898, the Irish designed the forward blade Sirocco centrifugal fan, which was widely used in various countries; In the 19th century, axial flow fan has been applied to mine ventilation and blast in metallurgical industry, but its pressure is only 100~300 Pa, and its efficiency is only 15~25%. It was not developed rapidly until the 1940s.

In 1935, Germany first adopted axial flow isobaric fan for boiler ventilation and induced draft; In 1948, Denmark made the axial-flow fan with adjustable blades in operation; Rotary axial flow fan, meridional acceleration axial flow fan, diagonal flow fan and cross flow fan have also been developed.

In short, under the same power, the centrifugal fan has a large air volume and low pressure, while the roots blower has a high pressure and small air volume

Main purpose and scope of use of Roots level dedusting fan