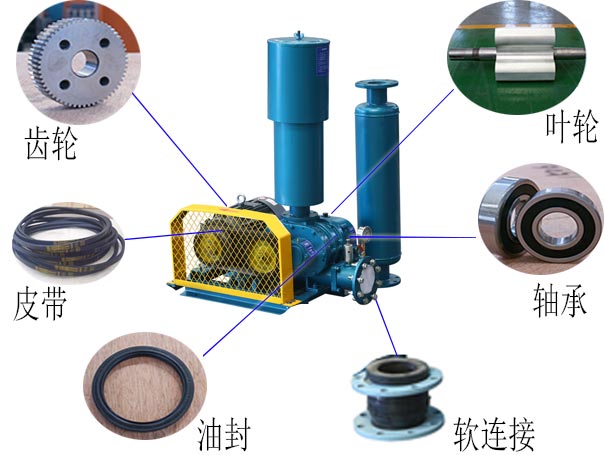

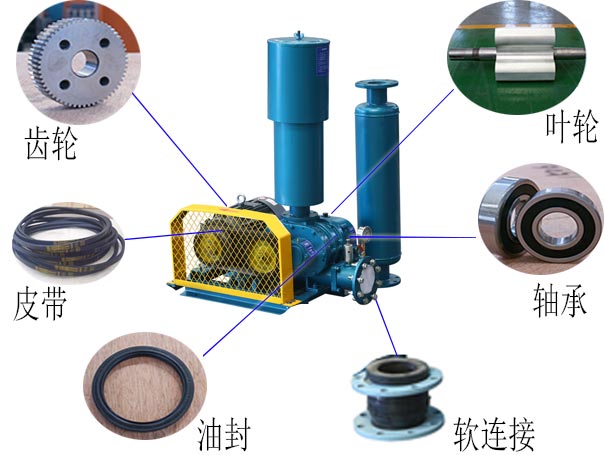

Roots blower is economical and durable, needs no lubrication, has a longer service life, and has good dynamic balance. Due to improper operation or long-time operation of Roots blower, the motor will make abnormal noise, the belt will heat up, and other phenomena will affect the normal operation of Roots blower. Fine particles entering the Roots blower will easily cause fan abrasion, and the clearance between impeller, bearing, and gear will become larger, This will cause a lot of noise and heavy load when rotating. Dry grinding of the belt will easily cause belt fracture. Long time operation will burn the roots blower. It is necessary to stop the roots blower as soon as possible and repair it in time, otherwise more parts will be damaged.

We all know that Roots blower has small gas pulsation, small vibration, low noise, simple structure, stable operation and stable performance, and is suitable for many purposes. It has been widely used in many fields. Roots blower is a positive displacement fan with forced gas transmission characteristics. As a rotary mechanical equipment, Roots blower has relatively stable working characteristics. There are small gaps between rotors of Roots blower, between rotors and pump bodies, between rotors and side covers, so there is no friction or contact wear in the working chamber.

Roots blower is economical and durable, needs no lubrication, has a longer service life, and has good dynamic balance. Due to improper operation or long-time operation of Roots blower, the motor will make abnormal noise, the belt will heat up, and other phenomena will affect the normal operation of Roots blower. Fine particles entering the Roots blower will easily cause fan abrasion, impeller and bearing damage The gear clearance becomes larger, resulting in loud noise and heavy rotating load. Dry grinding of the belt is easy to cause belt fracture. Long time operation will burn out the roots blower. It is necessary to stop the roots blower as soon as possible for timely maintenance, otherwise more parts will be damaged.

1. After the bearing is worn, if its clearance increases to exceed the specified value, the two shafts supported by the bearing will vibrate and make abnormal noise. When the vibration is transmitted to the impeller, it may also damage the impeller clearance, making the impellers collide with each other, causing greater abnormal movement and noise. Solution: Replace the bearing.

2. Gear wear or loose gear fixation may cause abnormal noise of the gear itself, and damage the clearance of the impeller and the synchronism of the impeller rotation, resulting in more abnormal noise caused by the collision between the two impellers. Solution: Replace the gear.

3. The noise of roots blower increases with the increase of pressure rise. When the pressure rise fluctuates greatly, the noise will also fluctuate, forming a different sound. This abnormal noise can be reduced by checking the pipeline and load, eliminating the blockage, and ensuring that the pressure rise is stable at the specified value.

4. When the safety valve of Roots blower is opened, sharp exhaust noise will be generated at the safety valve. When the safety valve is repeatedly opened and closed, an abnormal sound will be generated. Solution: Check whether the fan is overpressure or adjust the safety valve - the fan is severely overpressure, the safety valve is opened, the safety valve is closed after the pressure drops, but the pressure soon becomes overpressure again, so that the safety valve is repeatedly opened and closed.

5. The serious overload of the fan causes shaft deformation, which makes the impellers collide with each other and produce abnormal movement and sound. Solution: adjust the working condition, eliminate overload, and readjust the impeller clearance.

6. The fan is overloaded and overheated, causing deformation of the impeller and casing, resulting in friction between the impeller and casing, and producing abnormal noise. Solution: check the filter, outlet back pressure and system pressure, reduce overload and overheating, and increase the clearance on the inlet side of the casing if necessary.

7. The belt tension is too tight or too loose, which makes the speed of the fan unstable. If it is fast or slow, the gear will emit a whistling sound. Solution: Adjust the belt tension to appropriate.

8. The looseness of the base bolt and poor connection may also cause the fan to make noise. Solution: Fasten the bolts.

9. There are foreign matters, which jam the impeller clearance and make the impeller out of balance, causing vibration and abnormal sound. Solution: Remove foreign matters.

I believe that after reading the above, you should also understand the cause of the abnormal noise of Roots blower. I hope it will be helpful to you.

Text term label: Roots blower

Link to this article: //wuhanzhcs.com/html/news/n02/701.htm