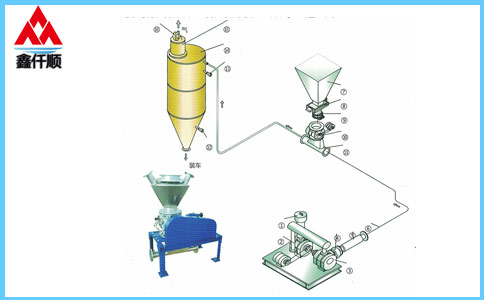

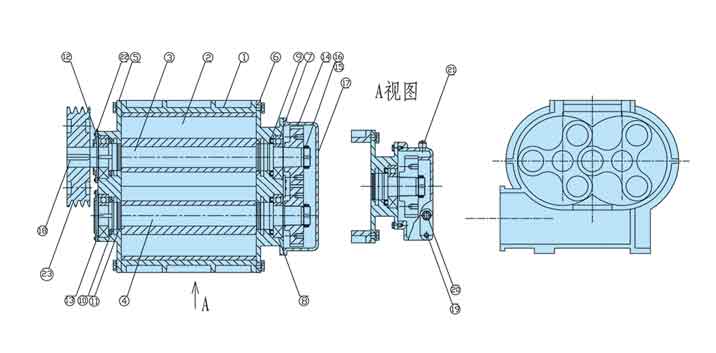

Working principle of Roots blower Working principle diagram of SR three leaf Roots blower Gif animation

Source: Roots blower manufacturer

Released on: November 23, 2021

Hits:

The impeller is contaminated with impurities, resulting in too small clearance; Gear wear causes large backlash; The gear is not firmly fixed and cannot keep the impeller synchronized; The bearing wear causes the clearance to increase. Remove the dirt and check whether the internals are damaged; Adjust the gear clearance. If the gear backlash is greater than 30%~50% of the average value, replace the gear; Reassemble the gear and keep the taper fit contact area up to 75%; Replace the bearing;

Incorrect installation clearance; The operating pressure is too high, exceeding the specified value; The operating temperature is too high; The casing or base is deformed, and the fan positioning is invalid; The axial positioning of the bearing is poor. Readjust the clearance; Find out the cause of overload and reduce the pressure to the specified value; Check the installation accuracy and reduce the pipeline tension; Check and repair the bearing and ensure the clearance.

Related information

-

Introduction to working principle of Roots blower -

What is the working principle of stainless steel roots blower? -

What is the working principle of nickel plated Roots blower? -

Operating principle of oxidation roots blower -

What is the working principle of Roots blower? -

What is the working principle of Roots blower? -

What is the working principle of Roots blower? -

Working principle and characteristics of roots blower for pneumatic conveying -

What is the difference between the working principle and characteristics of pneumatic conveying roots blower and air compressor? -

The manufacturer of Roots blower will explain the working principle of Roots blower:

Xinqianshun's latest products

Random articles

-

Roots blower fault, cause analysis of overcurrent fault of roots blower -

What are the precautions for cleaning Roots blower? -

How to reduce aeration of Roots blower? -

(Common sense necessary for selection of Roots blower) Calculation method of Roots blower speed: -

Causes of Roots blower motor burnout -

How can Roots blower be maintained and have a longer service life? -

Basic Measures for Cooling Roots Blower in High Temperature Season -

Roots blower is also the core electromechanical equipment necessary for sewage treatment aeration tank -

Application of three blade roots blower in sewage aeration _ sewage aerator: -

How to solve the noise problem of roots blower?

Latest news articles

-

How to repair the surface defects of Roots blower impeller? -

How to remove the bearing of Roots blower? -

What principles should be followed in the maintenance of three leaf roots blower? -

How to handle the wrong lubricating oil for Roots blower? -

Performance characteristics and maintenance of Roots blower for aquaculture -

How to select appropriate Roots blower aerator for aeration in aquaculture? -

What principles should be followed in the maintenance of three leaf roots blower? -

Notes on installation of safety valve of three blade roots blower -

What are the causes of tripping of Roots blower frequency converter? -

Introduction to the Main Causes of Abrasion of Three blade Roots Blower Impeller